Expertise

Silcoplast combines world-class technologies and in-depth expertise to achieve outstanding manufacturing results. Our qualifications span LSR, HTV, THP, tool and mould making and 3D printing, enabling us to provide you with precise, efficient and customised solutions. With a clear focus on innovation and quality, we optimise your requirements and ensure that our products meet the highest standards.

LSR

At Silcoplast, we utilise LSR (Liquid Silicone Rubber) technology to produce highly precise and flexible silicone components. This method enables us to produce products with exceptional elasticity and resistance to extreme conditions.

Silcoplast's use of LSR technology allows us to pour liquid silicone into precise moulds to produce components with excellent flexibility and strength. This advanced method ensures even material distribution and outstanding performance of our silicone products, even under the most demanding conditions.

HTV

At Silcoplast, we use HTV (High-Temperature Vulcanisation) technology to produce high-performance rubber components with exceptional durability. This advanced technology enables us to manufacture reliable and durable products even under extreme conditions.

At Silcoplast, we use HTV technology to manufacture rubber components that impress with their high temperature resistance and durability. This method ensures uniform vulcanisation of the material, enabling us to offer products with outstanding performance and reliability.

THP

At Silcoplast, we integrate THP (thermoplastic high pressure moulding) technology into our production processes to ensure the highest quality and efficiency. This advanced method enables us to produce complex plastic parts with exceptional precision and strength.

By using THP technology at Silcoplast, we can mould thermoplastic parts under high pressure, which enables precise and reliable production. This technology allows us to produce even complex and specific components with excellent surface quality and strength, enabling us to meet the demanding needs of our customers.

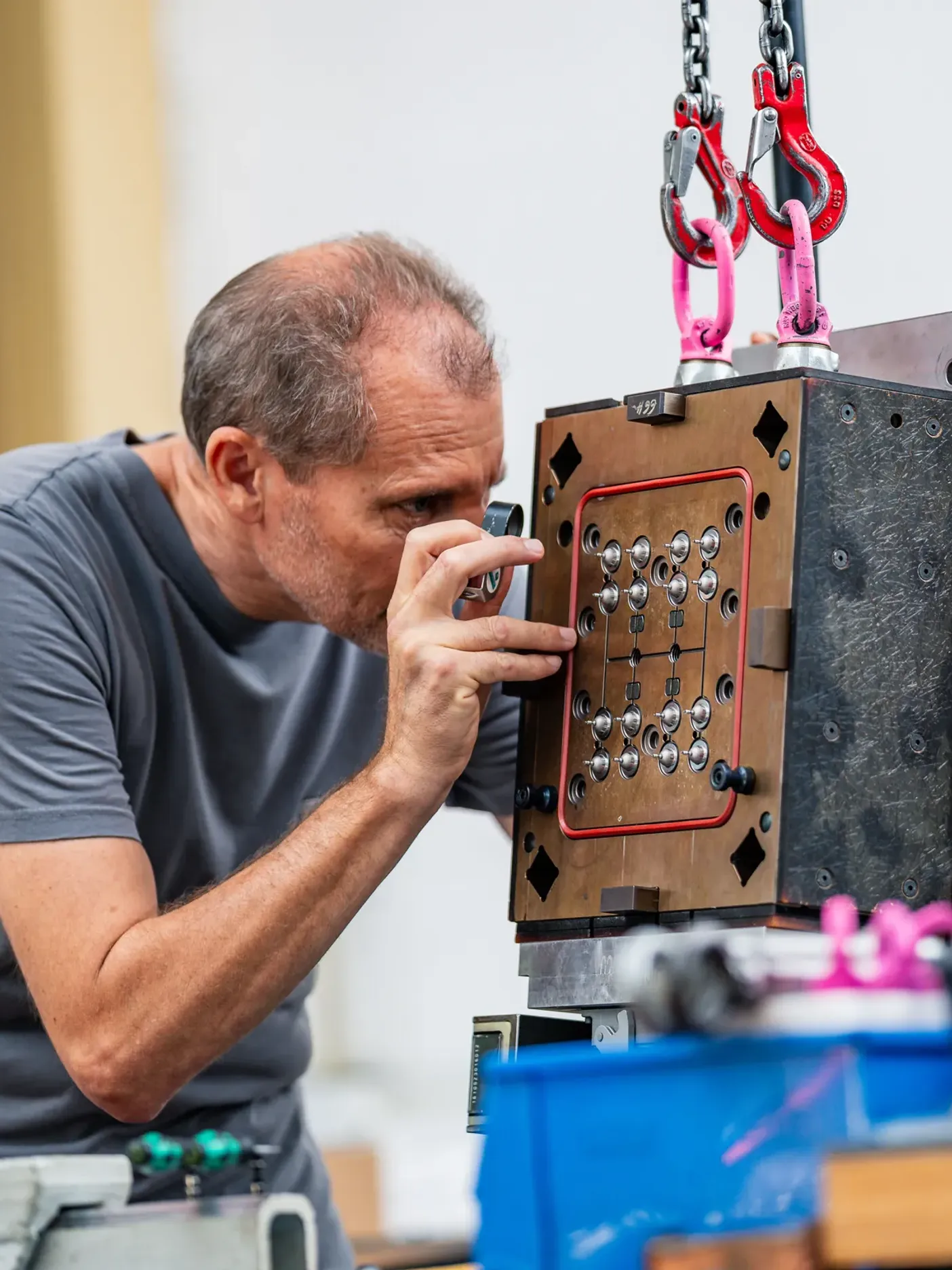

Tool/ Mould

At Silcoplast, we see tool and mould making as the key to precise and efficient manufacturing processes. With top-tier technologies and customised solutions, we create the basis for innovative plastic products of the highest quality.

At Silcoplast, toolmaking and mould construction are essential components of our manufacturing processes. With over 57 years of experience, we develop customised tools and moulds that are tailored to the specific requirements of our customers. Our team utilises the latest technologies to achieve maximum precision and efficiency in production. Through close cooperation and individual solutions, we guarantee that every tool and mould meets the highest quality standards. At Silcoplast, tool and mould making form the foundation for our innovative and reliable plastic solutions.

3D printing

Silcoplast has been defined as a centre of excellence of the Rico Group. This nomination underlines our leading role and expertise in 3D printing and innovative manufacturing technologies. As part of the Rico Group, we benefit from extended resources to offer you even more precise and advanced solutions.

Click here to go to our 3D website:

Silicone 3D-printing - Customized solutions for prototypes & series

At Silcoplast, 3D printing is a key area for our innovation strategy. On a dedicated website, we show how 3D printing enables us to develop flexible and efficient solutions to complex challenges. This advanced manufacturing process is revolutionising product development, particularly in medical technology, through the rapid creation of prototypes and complex shapes. Our team of experts utilise the latest printing technology to ensure the highest precision and quality and work closely with our customers. Visit our website to learn more about our 3D printing capabilities and turn your visions into precise products.

Specialties

Silcoplast combines advanced technology with extensive expertise to provide innovative solutions for different industries. Our commitment to precision manufacturing and customised approaches ensures that we reliably meet our customers' specific requirements.

Our broad expertise ranges from the processing of advanced silicone materials such as LSR and HTV to innovative solutions with THP and 3D printing. Thanks to latest technologies in tool and mould making, we offer precise production and high flexibility for a wide range of applications. We customise our solutions to meet the specific requirements of our customers. Our expertise enables us to efficiently realise both simple and complex projects. In this way, we guarantee first-class quality and optimum results for various industries.